Mitigating Heat Loss in Boiler Rooms

EDIT (April 29th, 2021): We’ve made changes to the featured image and revised the copy to better reflect issues our clients faced previously.

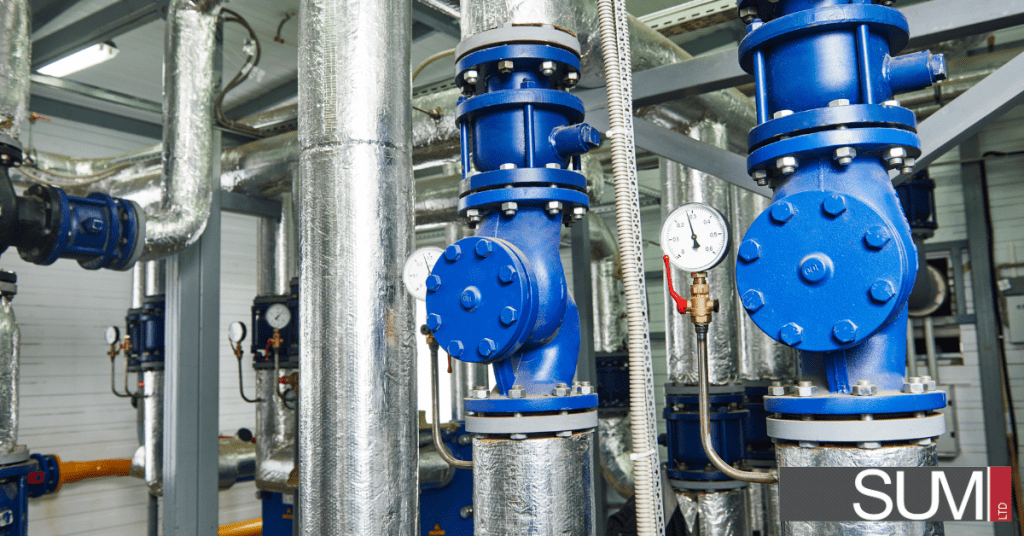

Hot boiler rooms caused by inefficient infrastructure can create a variety of problems in commercial or industrial buildings, radiating heat in a single room before reaching the intended destination. Radiant heat from these rooms are much hotter than one would think. When this heat rises, the ceiling and floor directly above can be as warm as 46°C. Those that occupy the space above may find it uncomfortable, opening windows or turning up the air conditioning. In either case, this constant battle to reach a comfortable temperature is a waste of both energy and money.

In addition, Boiler rooms can be extremely uncomfortable for your staff to work within. Not only can a boiler room’s equipment and surfaces pose a risk of burns, but the risk of heat exhaustion can also be extremely high. Covering a bare boiler creates a barrier between your staff and hot pipes, improving workplace safety.

What is a boiler?

A boiler is a closed vessel where a fluid, either water or steam, is heated and transferred to its various intended areas of use and sent back to the boiler to be warmed up again. From the warm water that is found in your sinks to the central heating systems for large commercial buildings, boilers are one of the most common systems used today. The fluid of choice for heat transfer is water due to its low cost and relatively high heat conductivity when compared to other fluids.

These boilers (including the pipes that transfer the fluid) require insulation to retain the desired temperature before being transported. Insulated boilers transport heated fluids to their desired locations and mitigate the rise of ambient temperatures within unintended areas, thereby reducing cost of gas to heat boiler fluid and saving you money.

How do I identify the areas of my boiler losing heat?

First and foremost, do not touch boiler pipes! Boiler pipes that transport steam and other hot fluids can reach temperatures above and beyond 95°C. Take the necessary precaution beforehand. Ensure that you have the necessary personal protective equipment before taking on this task. Identify the components that contribute the greatest heat loss using a thermal imaging gun like FLIR. In most systems, this would be the first pipe to leave the boiler. Follow the pipe down the line and locate a large pipe relative to the size of the other pipes. This pipe, known as the boiler header, is notorious for contributing to a high amount of heat loss. Insulating this component is the best place to start for cost-effectiveness and efficiency. If you would like to find other areas of opportunity to retain heat within your boiler room, book a consultation with us today.

What are my solutions for mitigating heat loss?

Once you’ve found the components that contribute the most to your boiler’s heat loss, you’ll need a product to retain this heat. SUM Ltd. creates custom removable insulation blanket that fit perfectly for situations like this, for both your boiler and its pipes. Each boiler room is different in terms of layout, size, exit and entry points, and the construct of the boiler itself. A custom solution ensures that your insulation blanket fits perfectly with your equipment. Not only will this prevent additional heat loss, but insulation blankets will also protect your staff from bumping into hot surfaces. SUM Ltd takes the measurements of your boiler (or any other equipment for that matter) very seriously. Taking precise measurements is the key to assembling a highly efficient insulation blanket. Our blankets are tool-less and take only a few minutes to remove and re-apply, making it easy for your staff to perform maintenance on your boilers whenever necessary.

Conclusion

Heat loss is the biggest contributing factor of energy loss within a boiler room. Optimal fluid temperatures may not reach their intended heating locations and may cause rooms adjacent to the boiler room to reach uncomfortable temperatures. If you’re looking for ways to improve the efficiency of your boiler room and reduce heating-related expenses, installing a custom insulation solution within your pipes and boilers is a top priority. Contact SUM Ltd today to discuss how we can assemble a custom solution for your boiler room.