At SUM Ltd, we believe analysis and data should be at the heart of every company—especially those that must demonstrate a quantifiable performance of their product. Without data, one cannot measure their performance. Without knowledge, one cannot proactively take action.

That is why SUM Ltd is always striving to expand our knowledge of the industry. We have our ears to the ground listening for changes so we can acknowledge an opportunity, plan a course of action, and adapt accordingly. In a new monthly series of blog posts, SUM Ltd would like to share a few samples from our research to our readers while giving credit to those that provide value to the industry in an insightful and engaging way. Personnel working in various departments at SUM Ltd will also draw from their expertise to provide additional insights.

A Different Perspective: What to Know About Ceramic Fiber

While ceramic fiber is typically used as insulation within the steel and foundry industry, insulation.org presents other industries that take advantage of ceramic fiber’s naturally high tolerance to heat. The market size of ceramic fibers is significantly smaller at a ratio of approximately 20:1 within these industries, but nonetheless play an integral role to their operations. Gary Bases from Insulation.org covers two types of industries: Power and Solar Power. To learn more, check out their blog post here.

Insulation Is an Investment and an Asset

Kim Melton from insulation.org writes an excellent blog on how insulation can be perceived as both an investment and an asset to a company thanks to its rapid return on investment. Insulation systems do this by reducing the energy required to run the insulated instrument, resulting in a reduced cost to operate. During normal circumstances, this may take between 6 months to 2 years to fully pay back the investment. Once the initial investment cost is paid back, insulation systems continue to offer returns throughout its lifespan, thereby transforming it into an asset for the company.

In addition to this, we’ve also added our thoughts to this blog post below:

SUM Ltd’s Perspective

Insulation is of critical importance due to extremely cold temperatures that these lines are exposed to, thereby maintaining heat conservation, freeze protection and process stabilization. Looking at the numbers, the savings of energy start at 85% the moment you put on a single 0.5” layer of FG insulation. Now depending on all the other factors, from ambient temperature, pipe size, the type of product being transported, to the thickness of insulation, energy savings can vary from there. These same energy efficiencies equal proportional efficiencies in CO2 and NOx pollution reductions, not to mention the energy cost savings. All of our customers value the effect insulation has on their operations, but it’s only a proper fit that can provide these staggering results. Insulation also has additional uses beyond reducing energy expenses. Insulation also protects personnel by mitigating potential hazards, such as being burned.

Finally, an Insulation Audit is the most important aspect from our perspective to identify, report and take action to mitigate deficiencies in our clients’ production systems. We see many insulation deficiencies—especially at older plants. It is a good idea to spread that study and make people in the industry more familiar with benefits of proper insulation. It would be beneficial to operations and the environment if deficiencies were taken care of in proper manner.

Up to $55 Million Boost for Alberta Businesses to Improve Energy Efficiency

While there may be several reasons as to why industrial and commercial businesses may take improving their energy efficiency as a lower priority, such as insufficient funds to allocate or other priorities taking precedence, the Government of Alberta has taken initiatives to make it an easier choice for small to medium-sized businesses within these fields to take action. Through Emissions Reduction Alberta, the Government of Alberta is funding up to $55 million to cover a portion of energy efficiency project costs.

To read this blog post, follow this link here.

SUM Ltd’s Perspective

Improving efficiency via emissions reduction projects is of critical importance to many oil plants operations. We supplied all soft cover blankets for one of these oil plant operations where it was the first of its kind, intended to significantly reduce that plants emissions. After being operational for 9 years, it has successfully reduced the company’s emissions by 80%.

Newer equipment often has greater energy efficiency than its predecessors. Unfortunately, even some of the best of today’s technologies have yet to achieve 100% efficiency. In this context, both newer technologies as well as legacy technologies are well served with insulation that can decrease heat loss, leading to decreased energy use and consequently a decrease in pollutants.

Insulation Audit Leads to Big Savings

Zach Tanghetti from insulation.org guides us through one of their case studies. This time, he takes a deep dive on Honeywell’s site at Geismar, Los Angeles where the regulation of temperature of various process fluids, such as refrigerants, hydrofluoric acid and medical packaging resin is of critical importance. Undergoing their insulation audit, several areas of the site were found to have insufficiencies with significant potential energy and financial savings.

SUM Ltd’s Perspective

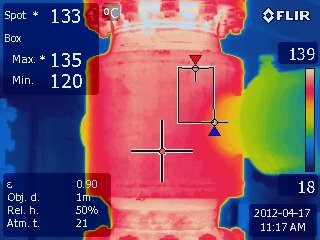

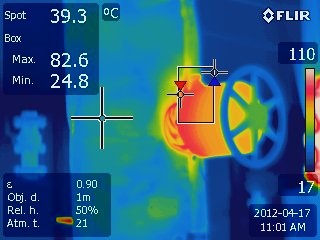

Using a FLIR camera you have a quantitative picture of how much energy you save by installing proper insulation. These kinds of audits, or a quick shot with the FLIR camera, can also show where there are gaps in, or inexact installations of, already existing insulation.

Conclusion

In order to provide the best insulation products for our customers, SUM Ltd analyzes trends and changes within each industry; these blogs are a small sample of our constant research to improve. Without data, you cannot measure your performance— and measuring quantifiable performance is at the heart of our company.

SUM Ltd builds custom-fitted insulation blankets for every project. To us, perfection is the only standard, and a job well done is a blanket that precisely matches every bend, curve, or loop of your instrument. To achieve this, our dedicated staff members always measure and remeasure your instrument. After all, we are firm believers of measuring twice and cutting once.

Our attention to build quality has earned us the trust of companies around the world. You can find our insulation on North Sea drilling platforms, Argentinian instruments, or right at home in BC ships and mines. If your instrument requires custom insulation, book a consultation with SUM Ltd today.