At SUM Ltd, we evaluate each project carefully before selecting the materials to use in the production of the custom-fitted insulation blankets needed for that specific project. Stainless steel mesh often proves to be extremely versatile, durable, and affordable as our choice of insulation material for various projects.

Stainless steel mesh can be made up of several types of alloys with varying concentrations; however, different alloys may produce different results. At a glance, two samples of stainless steel may seem identical, but they may hold important differences in temperature resistance, hardness, ductility, magnetic response, corrosion resistance, and more. When considering using stainless steel mesh for your custom removable insulation blanket, SUM Ltd can help. SUM Ltd’s trained experts spend the extra time to precisely measure your instrument’s dimensions, allowing us to manufacture a long-lasting, durable blanket capable of resisting even the harshest conditions.

What is stainless steel mesh?

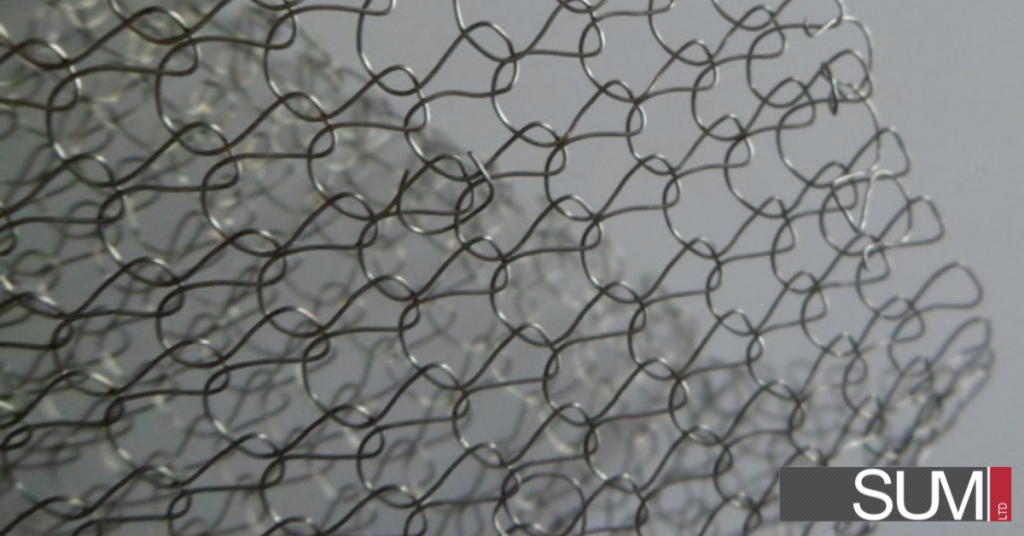

Stainless steel mesh is a type of casing used in custom removable insulation blankets designed to protect instruments from a variety of elements. Stainless steel mesh is most commonly manufactured using 304 grade austenitic stainless steel, but depending on the insulation blanket’s requirements, other grades may be used.

Stainless steel families & grades

Before we begin to understand stainless steel mesh, we first need to understand the properties of stainless steel itself. Depending on the client’s specific needs, varying compositions of alloying metals may offer a differing set of properties than another. These varying compositions are categorized by grades. For example, within austenitic stainless steels, the client may request grade 302 for its greater mix of carbon in their stainless steel, resulting in increased strength, whereas another client may need less carbon in their mix to assist in welding operations. Grades of stainless steel that exhibit desirable traits for its intended application must be considered when producing stainless steel mesh.

Grades are then grouped with stainless steels with similar compositions of alloying elements and properties, known as families. There are four families: Austenitic, ferritic, duplex, and martensitic.

Family #1: Austenitic stainless steel

The most popular of stainless-steel families, austenitic stainless steel consists of 16-26% chromium, 6-12% nickel and iron. Molybdenum, manganese or other alloying elements may also be added to create desired properties. Generally speaking, austenitic grades fall within the 300’s category.

One of the most popular grades of austenitic stainless steel is grade 304. By the standards set by the Society of Automotive Engineers (SAE), it must contain:

- 18% to 20% Chromium

- 8% to 10.5% Nickel

- 0.08% Carbon

- 2% Manganese

- 0.75% Silicon

- 0.045% Phosphorus

- 0.03% Sulfur

- 0.1% Nitrogen

Family #2: Ferritic stainless steel

On a molecular level, ferritic stainless steel receives its name from the soft metal that forms its microstructure, known as α-iron (alpha-iron) or ferrite. Ferritic stainless steel contains a low nickel content, making it more cost-effective than other families, and can contain high concentrations of iron, causing the material to be generally magnetic, depending on its grade. Certain grades can also contain chromium levels as high as 27%. Other metals include molybdenum, niobium, silicon, and/or titanium. You can find ferritic stainless steel used in applications such as petrochemical, heat exchangers, furnaces, and appliances.

Family #3: Duplex stainless steel

Duplex stainless steel combines the desirable characteristics of both ferritic and austenitic families, often at a lower cost. Common components of duplex stainless steel include carbon, manganese, silicon, chromium, nickel, phosphorus, and sulphur. Depending on the grade, molybdenum, nitrogen, and copper may also be found in the final product.

Much like the families it is derived from, duplex stainless steel offers comparable corrosion resistance to that of austenitic grades and higher toughness and ductility than ferritic grades with a lower nickel content. Common applications include, but are not limited to, chemical and liquid processing, naval parts and components, construction, and pulp and paper production.

Family #4: Martensitic and precipitation hardening stainless steel

While martensitic and precipitation hardening stainless steel is the least common of the 4 families, it still demonstrates clear applications such as knives, razors, or medical/dental tools. Martensitic stainless steel can be hardened and tempered through heat treatment due to the added carbon. Other alloying elements include manganese, molybdenum and nickel.

Stainless steel family and grade SUM Ltd uses

While austenitic stainless steel’s superior corrosion resistance is a desirable trait, stainless steel mesh commonly uses this family primarily for its formability. Exploiting austenitic stainless steel’s formability property allows SUM Ltd to build custom insulation blankets to fit snugly to an instrument. As we’ve mentioned in our previous blog, the effectiveness of a removable insulation blanket hinges on the blanket properly fitting the instrument. Loose or improperly fitted blankets may significantly reduce its overall performance or potentially render it completely ineffective.

What are the benefits of using stainless steel mesh?

- Temperature resistance: Stainless steel mesh is capable of handling extremely high temperatures ranges of up to 1,260°C (2,300°F).

- Corrosion resistance: Thanks to its natural properties, stainless steel mesh is highly resistant to corrosion. Certain grades of stainless steel have a lower predisposition to stress corrosion cracking.

- Formability: Drawing stainless steel into thin wires, then weaving it into a mesh, as opposed to using sheet metal, is what offers stainless steel mesh its high formability without the added weight or compromising its temperature resistance.Mitigate gaps between your instrument and removable blanket to improve its overall efficiency with stainless steel mesh.

What are the applications for stainless steel mesh?

- Marine: Due to austenitic stainless steel’s natural ability to resist corrosion, stainless steel mesh is highly suited for marine environments.

- Aerospace: High formability to unconventional shapes, lightweight relative to sheet metal, and rapid removal and replacement for in-service inspection of protected equipment make custom removable insulation blankets with stainless steel mesh casings ideal for aerospace application.

- Heat conservation: Minimize process disturbances and energy loss using a custom removable insulation blanket with a stainless steel mesh casing.

- Employee personal protection: Adding a barrier such as our custom removable insulation blankets between equipment with high temperature surfaces drastically reduces the risk of burns.

Conclusion

As it is made clear, stainless steel mesh’s properties offer several advantages for custom removable insulation blankets including its light weight, high temperature resistance, and formability to an instrument’s shape. If these are the properties you require for a casing in your next insulation blanket, SUM Ltd builds long-lasting and efficient custom-fitted insulation blankets for your needs. To us, perfection is the only standard, and a job well done is a blanket that precisely matches every bend, curve, or loop of your instrument. To achieve this, our dedicated staff members always measure and remeasure your equipment. After all, we are firm believers of measuring twice and cutting once.

Our attention to build quality has earned us the trust of companies around the world. You can find our insulation on North Sea drilling platforms, Argentinian instruments, or right at home in BC ships and mines. Whether you decide to use stainless steel mesh as part of your custom removable insulation blanket’s casing or another material, book a consultation with SUM Ltd today and find what works best for your instruments.