Custom removable insulation blankets play a vital role in maintaining optimal temperatures for industrial equipment. To maximize their effectiveness, it is crucial to install these blankets with precision and expertise. At SUM Ltd, we take pride in our meticulous approach to insulation blanket installation, ensuring a perfect fit for all types of equipment. In this blog, we will explore the significance of accurate installations and provide insights on installing insulation blankets for challenging parts.

The Importance of Precise Installation

Installing insulation blankets that fit your equipment accurately offers several benefits. An ill-fitted blanket with gaps can compromise its effectiveness by allowing air to pass through, leading to energy inefficiency. Moreover, improper insulation can cause condensation and water damage, leading to corrosion over time. SUM Ltd understands these challenges and prioritizes precise measurements to deliver optimal insulation solutions.

Custom Solutions for Every Equipment

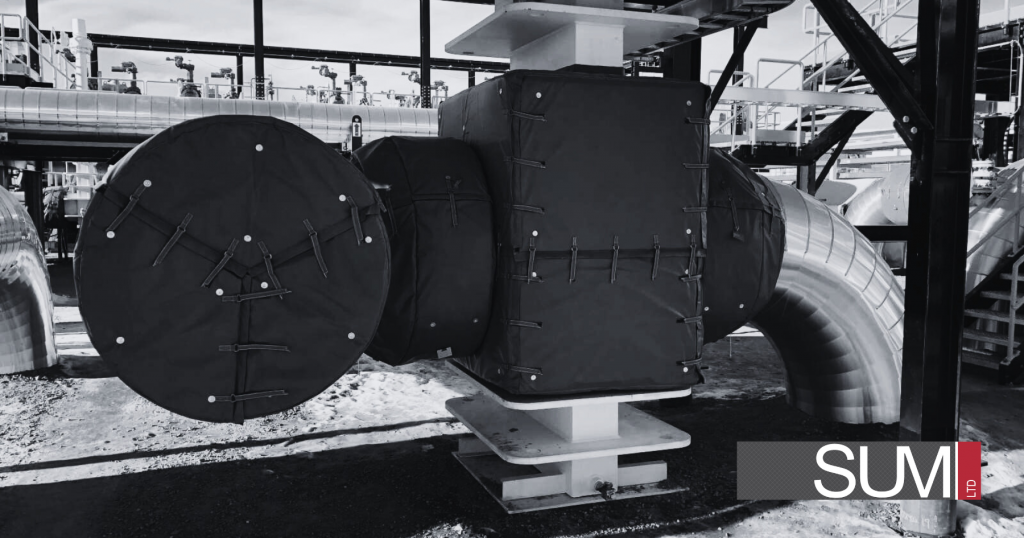

SUM Ltd specializes in custom insulation solutions tailored to fit a wide range of industrial equipment. From gate valves and steam traps to pressure reducing valves and flanges, we can design and build insulation blankets that perfectly match your specific requirements. Our trained and dedicated staff will visit your site to measure and assess the instruments that require insulation, ensuring a seamless installation process.

Efficient Installation Process

Unlike other companies that may require multiple attempts to achieve the right fit, SUM Ltd ensures timely and efficient installation. Our custom removable blankets feature a tool-less design, allowing for easy removal in just five minutes. This quick removal process facilitates equipment monitoring, maintenance, and routine inspections without hassle.

Tips for Installing Blankets on Challenging Parts

Certain equipment parts present unique challenges during insulation blanket installation. Here are some expert tips to overcome these difficulties:

- Segmented Elbows: When installing blankets on segmented elbows, curve the edges of the blanket to match the elbow’s shape. Secure the blanket using lacing wire, ensuring there are no gaps or voids.

- Flanges: Wrap the blanket around the flange and temporarily secure it with wire or lacing. Use the blanket’s drawcords to tighten it around the flange, removing the temporary wire and fastening the draw cords around the rivets.

- MineWrap™ Mark II Butterfly Elbows: Open the blanket and pull it over the elbow by curving the edges. Secure the blanket to the joint using lace wire.

- Purifiers with Cones: Open the blanket and curve it around the cone until the edges meet, conforming to the purifier and cone shape. Wrap the blanket with wire to secure it to the equipment.

- Manifolds: Installing insulation blankets on manifolds requires a more complex process. Fold the blanket around the manifold and create a loop on one end of the lacing wire. Follow a step-by-step procedure to wrap the wire around the manifold, rivets, and blanket, ensuring a secure fit.

Conclusion

Accurate installation of custom removable insulation blankets is crucial for ensuring energy efficiency, preventing damage, and maximizing equipment performance. SUM Ltd’s expertise in custom insulation solutions guarantees a perfect fit, thanks to meticulous measurements and precise installations. By following expert tips for challenging parts, you can overcome installation difficulties and optimize the effectiveness of your insulation blankets.

Ready to Get Started?

Are you seeking top-quality custom removable insulation blankets for your industrial equipment? Contact SUM Ltd today and benefit from our expertise in delivering precise insulation solutions tailored to your needs. Ensure optimal energy efficiency and equipment performance with our professional installation services.