One of the most common components to cover with soft insulation in petrochemical, chemical and oil and gas industries is industrial valves. Much like the rest of the system, industrial valves require insulation to minimize heat loss, increase energy efficiency, and keep contents flowing at the desired temperature. During sub-zero temperature conditions, custom industrial valve insulation blankets can also prevent the system from freezing. However, as these components must be kept accessible for maintenance and repair purposes, industrial valves require soft, removable insulation rather than hard, permanent insulation. For more information on the differences between soft and hard insulation, please see our previous blog here.

What are the most common types of industrial valves insulated by SUM Ltd?

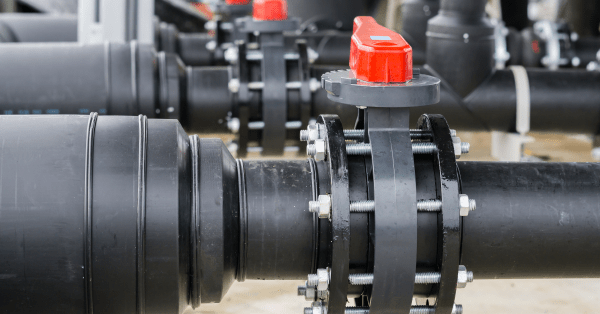

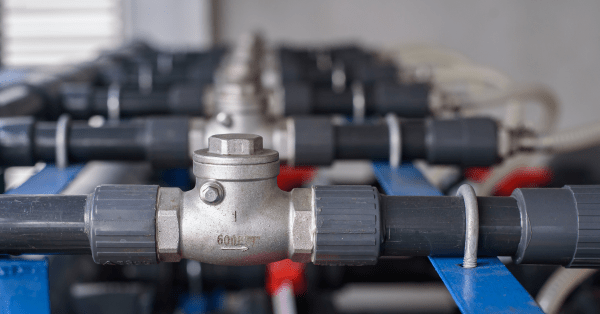

Ball Valves

Ball valves are a quarter-turn valve with a spherical disc inside to control flow. When the valve is turned to the “on” position, the disc moves and allows fluid to pass. When the valve is turned to the “off” position, the “ball” prevents flow from occurring. Ball valves are known for their ability to withstand high volume, pressures, and temperatures. Many ball valves operate in high temperature systems and can pose as a significant point of heat loss.

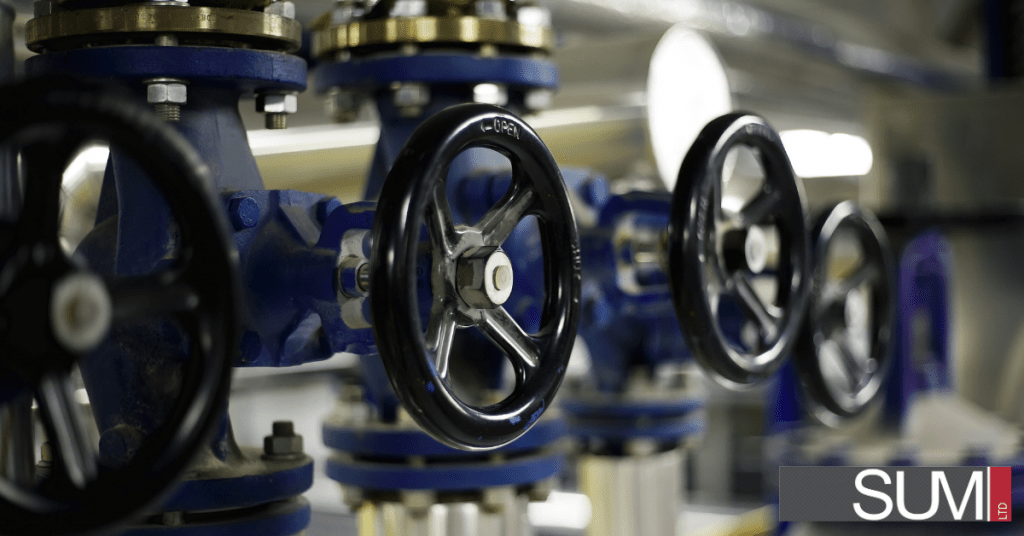

Globe Valves

Globe valves received their name from their original, unmistakable, spherical-shaped body design. Despite carrying the same name, modern globe valves do not have the same globe-like appearance. Globe valves operate by driving a plug into an internal gap using an actuator above the main body. Typically, the actuator comes in the form of a handwheel, allowing or restricting the movement of fluids. Due to its unusual shape, globe valves require custom insulation to fit snugly and ensure any exposed surface area is kept to a minimum. A bonnet can also be used to cover this valve.

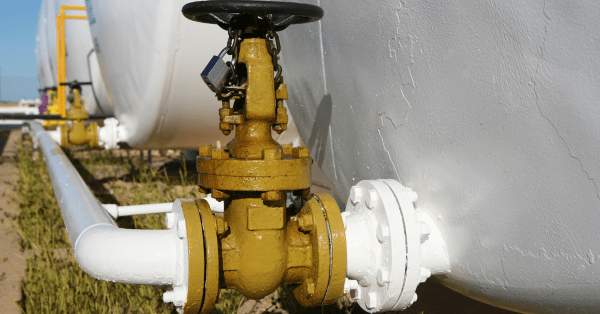

Gate Valves

Gate valves, also known as sluice valves, are commonly found in piping systems due to their relatively small size and sealing performance, allowing or restricting the movement of water, oil or other liquids. Much like globe valves, a custom soft insulation’s flexibility and ease of removal makes it a suitable choice to insulate gate valves’ irregular body shape. Just like the globe valve, a bonnet can also be used to cover this valve.

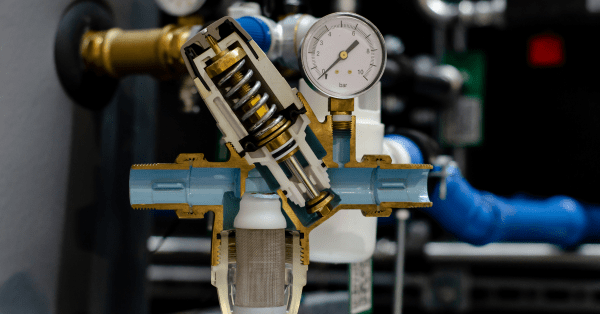

Pressure-Reducing Valves (PRVs)

Pressure-reducing valves, or pressure regulators, are used just as the name suggests: to lower the pressure of high-pressure fluids to meet the needs of the intended application. Most PRVs that require insulation are connected to systems that generate highly pressurized steam.

Air Release Valves

Also known as air relief valves, air release valves release unwanted air trapped inside of a piping system, increasing the throughput of the system. By default, the valve is in an open position to allow air to escape. When liquid rises, a poppet floats up and closes the valve. Air release valves could require insulation in colder climates where it can be at risk of freezing, rendering the air release valve inoperable.

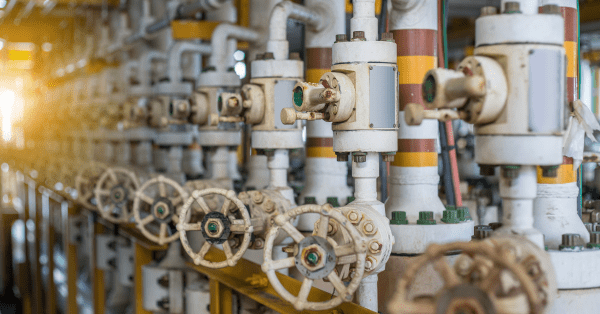

Butterfly Valves

Butterfly valves work similarly to ball valves: They are both operated manually and have a component inside that allows or restricts the flow of fluids. The key difference is that butterfly valves use a metal disk that is flat and round to regulate flow. The body of butterfly valves are almost always made of steel. As steel can have a high thermal conductivity, insulation can be especially useful in applications such as steam systems to improve personnel safety and energy efficiency.

Check Valves

Check valves are valves that allow fluid flow in one direction only. Also known as one-way valves, check valves can be used to prevent backflow and hydraulic shock. These valves can commonly be found downstream of steam traps to prevent condensate backflow. A bonnet can also be used to cover this valve.

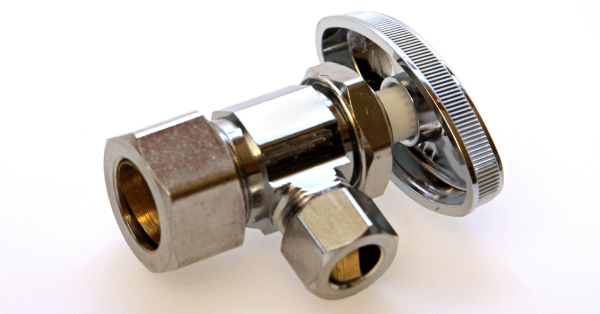

Angle Stop Check Valves

Angle stop check valves are used as shut-off valves for sections of a system. This allows maintenance and repair personnel to perform their work easily without shutting down the entire system. Due to its complex shape, however, angle stop check valves can be difficult to insulate without custom soft insulation.

Steam Traps

Steam traps are industrial valves used to discharge condensate and non-condensable gasses within a steam system. A steam trap’s valves automatically open and close based on condensate levels. As steam traps are intended to release undesired gasses and condensate away from the system, their surfaces can become quite hot. This poses as a safety hazard for personnel working in the surrounding area. Insulating steam traps with soft insulation not only mitigates this risk, but also improves the system’s overall efficiency. Furthermore, custom soft insulation is easily removed and reapplied, allowing maintenance and repair personnel to work unobstructed.

Plug Valves

Plug valves are type of industrial valve with a cylindrical plug with one or more openings. Rotating the plug using a handwheel will allow or restrict the flow of fluids. Plug valves are often used in systems when quick and frequent on-off operation is needed. If your system handles high temperatures, insulation is often recommended to improve its overall efficiency. In addition, soft insulation is often preferred over other solutions as these valves require frequent and regular access.

What are some of the variables to consider when insulating industrial valves?

When deciding on a company that measures, designs, and builds custom removable insulation blankets, ensure they understand these variables:

Insulation thickness: Depending on your instrument’s needs, the thickness of the insulation blanket may vary. While the most common thickness is 1”, 1/2” thickness can be considered for small valves or if clearance may become an issue with thicker insulation. By contrast, 2” thick insulation can be used for instances for higher heat requirements or sound attenuation.

Proper fit: With such a wide variety of industrial valves to consider, including size, dimension and geometry, custom removable insulation blankets should match the part it is intended for. Each insulation blanket is truly unique, as the presence of adjacent valves or piping can also affect the final design. Positioning cut-outs is essential for a blanket to properly fit your instrument and function as intended.

Materials: Material choice can play a vital role to the longevity and performance of an insulation blanket. Ensure that the company you choose can offer you insight on what material may be effective for the conditions your instrument resides within. Is your instrument situated outdoors where it may be exposed to harsh winds, hail, sunlight and/or snow? Or does it reside indoors where it is frequently exposed to caustic chemicals? These variables may affect the material choice in your custom removable insulation blanket. For example, fibreglass insulation is an effective insulation material, but should not be used in environments that are frequently exposed to humid or wet conditions. Instead, consider other insulation alternatives such as mineral wool.

Conclusion

At SUM Ltd, we pride ourselves on our measurements, precision and getting the job done right the first time. Every instrument has its own unique shape and complex geometries. Therefore, we build custom-fitted insulation blankets for every project. To us, perfection is the only standard, and a job well done is a blanket that precisely matches every bend, curve, or loop of your instrument. To achieve this, our dedicated staff members always measure and remeasure your instrument. After all, we are firm believers of measuring twice and cutting once.

Our attention to build quality has earned us the trust of companies around the world. You can find our insulation on North Sea drilling platforms, Argentinian instruments, or right at home in BC ships and mines. Order a custom removable insulation blanket for your industrial valves today.