What is the Difference Between Hard and Soft Insulation?

Insulating your equipment has many tangible benefits for your company. For example, exposed components in a boiler system such as control valves and steam traps can pose a burn hazard for employees as it radiates heat into the surrounding area. Not only does installing insulation on exposed, hot surfaces create a barrier to protect employees, it also reduces energy costs by retaining radiated heat.

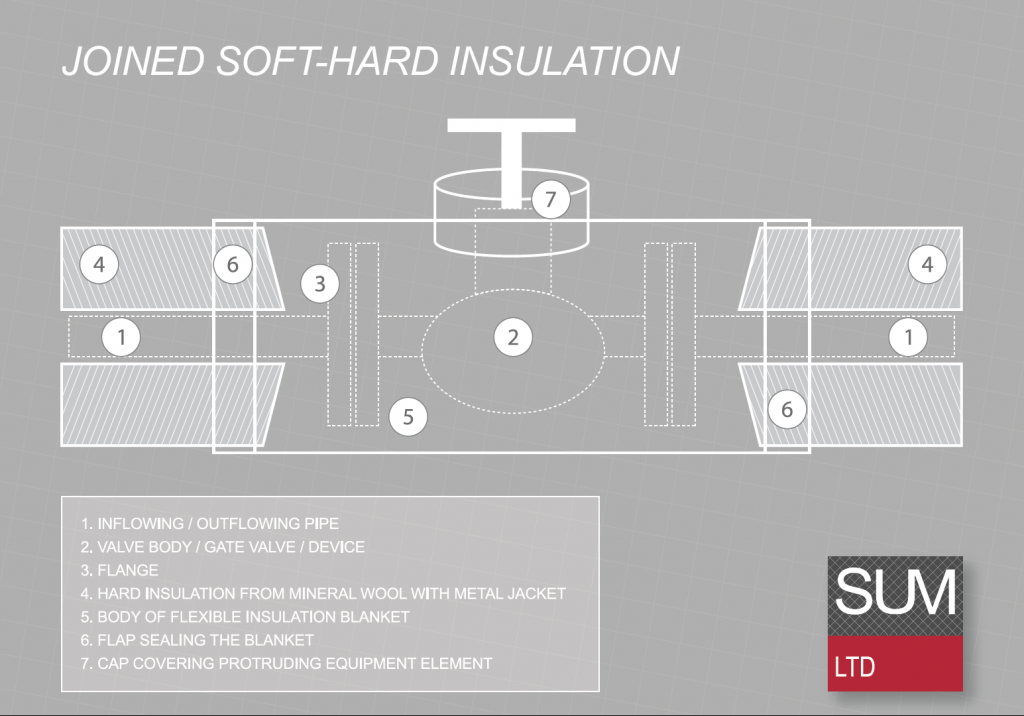

In an industrial setting, there are two types of insulation: Hard and Soft. One of SUM Ltd’s core competencies focus on building custom removable insulation blankets for any kind of equipment. But what exactly are the differences between hard and soft insulation? Which one do you need? Both types of insulation are effective in its respective uses. Depending on your situation, you even may require both. Let’s look at the differences in detail.

Hard Insulation

Permanence

Hard Insulation is built to last. When a user installs hard insulation on their infrastructure, they intend to never remove it.

Intended for Straight-Run Piping

Hard insulation is typically installed for long straight-run piping. The longer the straight piping, the more cost-effective it is when compared to custom-fitting it with soft insulation. In addition, long runs of straight pipes benefit greatly from permanent hard insulation due to its limited need for maintenance.

Insulation Contractor Required

If for whatever reason you need to remove your hard insulation, an insulation contractor is required to cut it to prevent damaging the internals. Once the cut and modifications has been made, the contractor must then replace the product and seal it back up. The owner of the infrastructure may incur charges for the hours the contractor needs to work.

Soft Insulation

Flexibility

One of the greatest advantages to soft insulation is its flexibility. This allows the insulation to be custom built for any shape and size.

Toolless Design

Toolless Design is a greater benefit than you may think. Soft insulation can be removed and re-applied in a matter of minutes. By comparison, hard insulations require several hours to remove and re-apply, saving both time and costs.

Intended for Unusual Shapes and Frequently Accessed Equipment

Custom-built soft insulation is your best solution if your staff requires frequent access to the equipment you need insulated, or if the shape of your infrastructure is atypical.

In Conclusion

Hard insulation is a very cost-effective solution for long runs of straight piping. Ensure that you don’t need frequent access to this section of the pipe. If you need to remove the insulation for whatever reason, you will need to hire a contractor to remove and re-apply it, requiring several hours. However, if you need to insulate a part of your equipment that requires frequent access, or have an unusually shaped piece of equipment, soft insulation would be a better solution.

Whatever the solution you may need, hard and soft insulation work well in conjunction and create an overall safer work environment, while achieving higher energy savings through heat conservation.

Need soft insulation to protect your piping system components? Want to learn more about how we can build custom removable insulation blankets for your infrastructure? Our product can fit any shape and size you need. Contact us today!