Throughout history, glassmakers have experimented with glass fibres, pushing how fine a single strand of glass could be. The first fibreglass insulation product that was meant for commercial use was invented by Games Slayter nearly a century ago. At today’s scale of production, fibreglass is only made possible through finer machine tooling.

Fibreglass is one of SUM Ltd’s most popular materials for industrial and commercial building insulation, and it is also a common material used to insulate residential homes. Its widespread adoption can be attributed to how versatile the material is. For industrial purposes, fibreglass can be used in custom insulation blankets, flattened into a sheet, or even woven into a textile.

What is fibreglass?

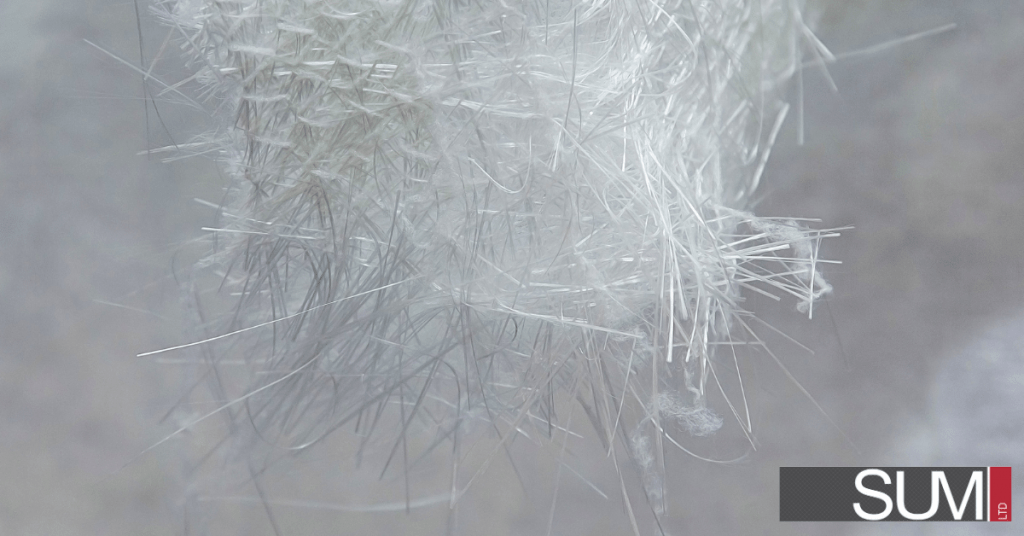

As the name suggests, fibreglass is a type of material made from extremely fine fibres of glass. These fibres are held together by a polymer to act as a reinforcing agent. Fibreglass’ main ingredients consists of sand (silicon dioxide) and recycled glass, known as “cullet”. Then, two other ingredients are added, each with their own distinct purpose: soda ash, or sodium carbonate, is used to reduce the melting point of sand and save energy, whereas limestone, or calcium carbonate, prevents the glass from dissolving in water.

The process of manufacturing fibreglass fibres is akin to making cotton candy and produces a similar, pillowy texture. The assembled ingredients are placed in a furnace that reaches 1,700°C or 3,000°F, creating molten glass. This molten glass is ejected into a spinning bowl with thousands of holes and forces the glass out, creating fibres. The fibres are vitrified and stretched using gas or compressed air, then dropped onto a conveyor belt where a polymer is applied. Steel plates compress the fibres as it makes its way to an oven heated to 260°C or 500°F, setting the polymer in place. Finally, the fibreglass is cut into batts of its specified dimensions, ready to be packaged and shipped.

Fibreglass insulation has several key properties:

- Density: Fibreglass has a relatively low density when compared to other types of insulation materials.

- Thermal conductivity: Fibreglass’ low density traps air molecules inside of its fibres, providing the material a low thermal conductivity.

- Water affinity: Fibreglass absorbs water and, when exposed, loses all insulation properties.

- Recycled material percentage: Fibreglass insulation uses up to 80% recycled glass.

What are the benefits of using fibreglass insulation?

- Flexibility: The natural properties of fibreglass offer excellent flexibility to cover unusually shaped equipment.

- Sound attenuation: Fibreglass is naturally sound-absorbent material and can significantly reduce sound transmission.

- Thermal insulation: One of the most common materials used for heat conservation is fibreglass. Fibreglass can withstand continuous heat of up to 540°C or 1,000°F.

- Easy installation process: Tool-less design requires only 5 minutes to remove, allowing staff to perform monitoring, maintenance, or routine inspections easily.

What are the applications for fiberglass insulation?

- Sound insulation: As an insulation material, fibreglass can absorb and dampen sounds, significantly reducing noise levels.

- Employee personal protection: Adding a barrier such as insulation blankets with fibreglass insulation inside between equipment with high temperature surfaces drastically reduces the risk of burns.

- Heat conservation: Minimize process disturbances and energy loss using fibreglass insulation.

- Freeze protection: Fibreglass insulation provides excellent resistance to extreme weather conditions when incorporated into heat traced blankets.

Conclusion

As a material, fibreglass has demonstrated its versatility through a wide variety of use case scenarios. Our next blog will be covering a variant of fibreglass with a different function: Fibreglass textiles.

If you are interested in integrating this insulation material into your next custom removable insulation blanket, SUM Ltd can help.

SUM Ltd builds custom-fitted insulation blankets for every project. To us, perfection is the only standard, and a job well done is a blanket that precisely matches every bend, curve, or loop of your instrument. To achieve this, our dedicated staff members always measure and remeasure your equipment. After all, we are firm believers of measuring twice and cutting once.

Our attention to build quality has earned us the trust of companies around the world. You can find our insulation on North Sea drilling platforms, Argentinian instruments, or right at home in BC ships and mines. If you need assistance with choosing the right materials for your custom insulation blanket, book a consultation with SUM Ltd today.