Throughout history, glassmakers have experimented with creating strands of glass fibres, pushing how fine a single strand of glass could be. The first fibreglass insulation product meant for commercial use was invented by Games Slayter nearly a century ago. At today’s scale of production, fibreglass and fiberglass textiles are only made possible through fine machine tooling.

Fibreglass textiles is one of SUM Ltd’s most popular materials for building industrial and commercial insulation. However, fibreglass can also be used as material reinforcement, electrical insulation, and even data transmission, leading to its reputation as a versatile material. In our previous blog, we discussed fibreglass as an insulation product. By weaving fine strands together, fibreglass can also be transformed into a textile.

What are fibreglass textiles?

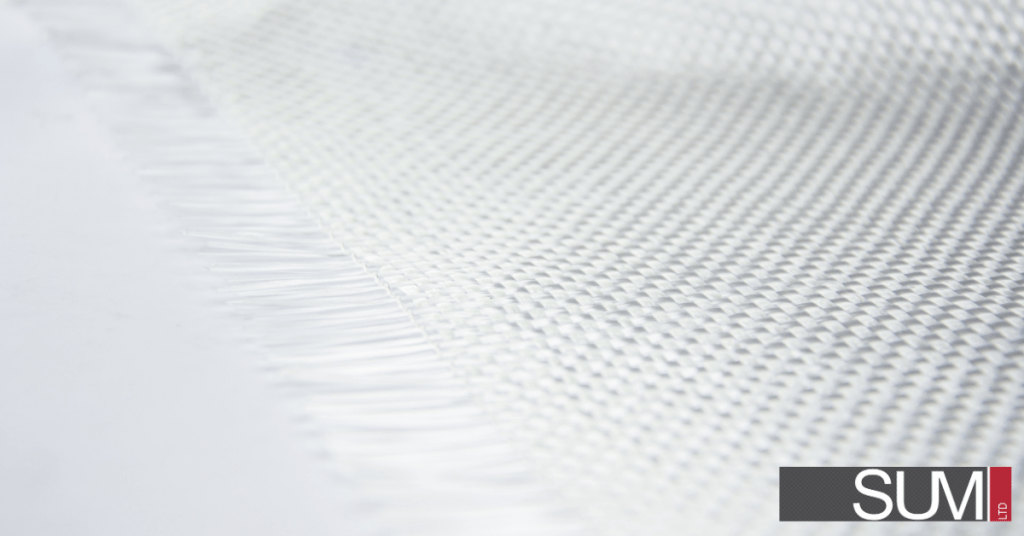

Fibreglass textiles are fabric-like materials made from weaving exceptionally fine glass fibre threads only a few microns thick. Thanks to their high tensile strength and pliability, fibreglass textiles can be used to strengthen products—even products with bends, curves or unusual shapes.

Fibreglass textiles are also highly effective thermal insulators and—when paired with an insulation material in a custom removable insulation blanket—can withstand high temperatures to protect employees or equipment.

Fibreglass textiles come in various weaves, depending on the customer’s needs:

- Plain weave: Plain weave is one of the most common weaves where each glass fibre crosses over and under alternately as it reaches another intersecting fibre. The over/ under crossing of the threads creates a rigid textile that does not unravel easily when cut or handled.

- Twill weave: Twill weave floats 2 or 3 intersecting fibres before crossing over/ under, creating a herringbone design. With less frequent over/under crossings of each thread, twill weave also forms a highly pliable weave that is stronger than plain weave styles.

- Satin weave: Satin weaves are the most pliable weave due to even less frequent over/under crossings. A single thread can float over 3 to 7 threads before crossing an intersecting fibre. Cutting a satin weave may cause the textile to unravel as each thread is not held as tightly.

Fibreglass textiles also come in a variety of different compositions that offer different properties:

- S-glass: Developed with a higher percentage of silicon dioxide than other variants, s-glass is designed to offer strong mechanical properties and withstand high temperatures.

- C-glass: Containing calcium borosilicate, C-glass was developed to have a high chemical resistance and handle corrosive environments.

At SUM Ltd, we specialize our fibreglass textiles offering for thermal insulation purposes.

What are the benefits of using fibreglass textiles?

- Lightweight: The diameter of individual fibreglass strands are only a few microns, making it extremely lightweight.

- High tensile strength: Using a variant with improved mechanical properties, such as S-glass, offers between 2 to 4.5 gigapascals of tensile strength.

- Thermal insulation: Fibreglass textiles can handle up to 1800°F (980°C) of continuous heat.

- Easy installation process: When deciding to use fibreglass textiles as part of your custom removable insulation blankets, our tool-less design requires only 5 minutes to remove, allowing staff to perform monitoring, maintenance, or routine inspections easily.

What are the applications for fibreglass textiles?

- Heat conservation: Minimize process disturbances and energy loss using fibreglass textiles.

- Employee personal protection: Adding a fibreglass textile insulation blanket between personnel and equipment can drastically reduce the risk of burns.

- Freeze protection: Fibreglass textiles as a component to a custom heat-traced blanket provides excellent resistance to extreme weather conditions.

Conclusion

If you are interested in integrating fibreglass textiles into your next custom removable insulation blanket, SUM Ltd can help.

SUM Ltd builds custom-fitted insulation blankets for every project. To us, perfection is the only standard, and a job well done is a blanket that precisely matches every bend, curve, or loop of your instrument. To achieve this, our dedicated staff members always measure and remeasure your equipment. After all, we are firm believers of measuring twice and cutting once.

Our attention to build quality has earned us the trust of companies around the world. You can find our insulation on North Sea drilling platforms, Argentinian instruments, or right at home in BC ships and mines. If you need assistance with choosing the right materials for your custom insulation blanket, book a consultation with SUM Ltd today.