Lauded as the quickest binders for fastening custom removable insulation blankets, hook and loop fasteners—or Velcro fasteners—create an excellent seal for heat retention and can be formed to fit even on unusually shaped equipment. With Velcro systems being made from different materials for different applications, SUM Ltd can design your custom removable insulation blanket’s fastening system to suit your company’s needs—regardless of the size of the project.

How were Velcro fasteners invented?

Velcro fasteners were invented as the result of a hunting trip in 1948. During this adventure, both, George de Mestral, and his dog became covered in burs from a burdock which were challenging to remove. Curious as to how the biomechanics worked, he examined the specimen under his microscope and found hundreds of tiny hooks that would catch on anything with a loop. More notably, however, was that this mechanism was found to be reversible and repeatable without losing degradation. After 10 years of trial and error and several prototypes, the first viable hook and loop mechanism was born.

Mestral originally created his hook and loop system from cotton; however, after only a few attempts, the system would degrade and eventually fail. Mestral sought after a stronger material to improve its lifespan. Depending on the application, hook and loop systems are generally made from three materials: Nomex, polyester, or nylon.

- Nylon: Durable, hydrophobic, and lightweight material, nylon is capable of withstanding high temperature variations, but is susceptible to ultraviolet light.

- Polyester: Polyester hook and loop systems are hydrophobic, lightweight, and resistant to ultraviolet light; however, the material has a low tolerance to high temperatures.

- Nomex: Developed by the DuPont chemical company, Nomex is a flame-resistant meta-aromatic polyamide (also known as m-aramid) material capable of withstanding up to 350°F or 177°C.

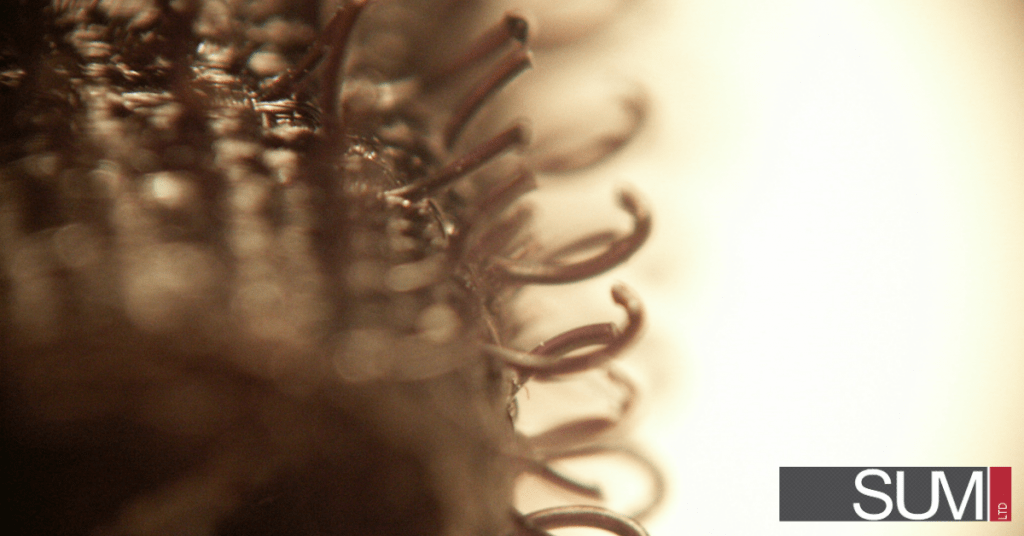

When it comes to manufacturing the material itself, there are two sides to consider: The hook side and the loop side. For the hook side, monofilaments of nylon or polyester are weaved under hot, infrared light, creating a loop. This loop is trimmed so that a hook is created. The area to cut and create the hook must be precise to adhere to the loop side. Inaccurate cuts could lead to faster material degradation and a less effective product. The loop side, or the soft side, is comprised of several thinner monofilament loops, creating a non-uniform appearance.

What are the benefits of using Velcro fasteners on custom removable insulation blankets?

There are several key advantages to using Velcro fasteners on your next custom removable insulation blanket:

- Price: Velcro fasteners are a cost-effective solution to bind your insulation blanket to your equipment when compared to other fastening system alternatives.

- Tool-less ease of installation: Custom removable insulation blankets with a Velcro fastening system do not require special tools to install.

- Speed of installation: Velcro fasteners require only 5 minutes to remove, allowing personnel to perform monitoring, maintenance, or routine inspections quick.

- No metal required: This is particularly useful if the insulation is covering certain kinds of steel or is touching sensitive equipment.

While Velcro fasteners can be used as the primary fastener of your custom removable insulation blanket, it is often used as a complementary fastener. Stainless steel lacing wire with rivets or Teflon straps with D-rings will add extra protection as your company’s need for better thermal protection increases. Of course, SUM Ltd is always here to help guide you through the decision-making process.

How do I properly care for custom removable insulation blankets with Velcro fasteners?

As Velcro fasteners are made of nylon or polyester hooks, care should be taken to ensure the nylon/polyester hooks do not come into contact with the hot surface of your equipment. Custom removable insulation blankets with Velcro fasteners should always be installed onto your equipment when it is cold to the touch. In addition, ensure the exposure of grime, dust, or other contaminants is mitigated in the Velcro fastening system. Failing to do so may render it ineffective or result in total failure.

Conclusion

Whether you are using Velcro, rivets with stainless steel lacing wire, or Teflon® straps with D-rings as your fastening system for your next custom removable insulation blanket, SUM Ltd can help.

SUM Ltd builds custom-fitted insulation blankets for every project. To us, perfection is the only standard, and a job well done is a blanket that precisely matches every bend, curve, or loop of your instrument. To achieve this, our dedicated staff members always measure and remeasure your equipment. After all, we are firm believers of measuring twice and cutting once.

Our attention to build quality has earned us the trust of companies around the world. You can find our insulation on North Sea drilling platforms, Argentinian instruments, or right at home in BC ships and mines. If you need assistance with choosing the right materials for your custom insulation blanket, book a consultation with SUM Ltd today.